As I mentioned in the Going solar! post, my new solar electric system is using microinverters located on the back of each panel to optimize power production. All of them then connect in parallel on the AC side, running essentially independently. As an added benefit we get individual panel’s data. Let’s look into that in a bit more details.

Shading/obstruction:

Say we have a foot of snow on the roof, (a very likely scenario in my neck of the woods) or a pile of bird poop in other parts of the country. And say I have a special pole to clean it off. I can get to some panels, but not to others. So what happens then? Well, those that do get some “pole attention”, wake up and start producing energy, completely unaware of the others being still buried under snow. So we go from no generation to some generation as long as I clean off a few panels. If we replay the same scenario in a typical DC series string of 10+ panels connected to one large inverter, the results will be a bit different. The panels that get no light will end up shunted by the bypass diodes in them to at least let some current through. Panels with some light will still produce, but the current will drop. Since all of them are in series, the “weaker” ones are now limiting the current from the fully exposed ones.

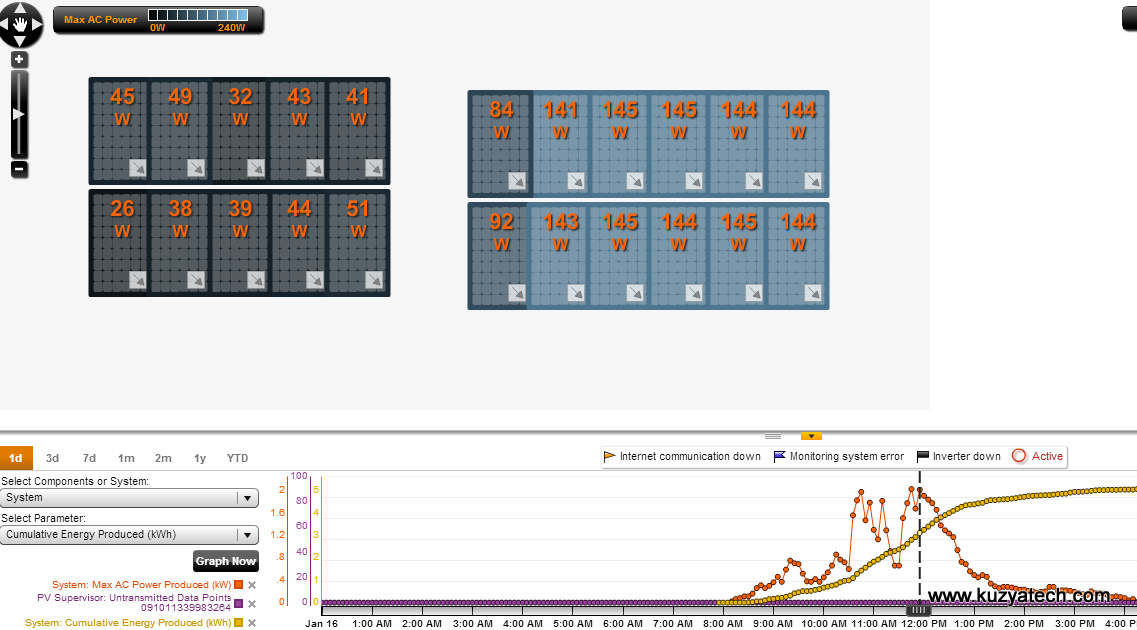

Moving sun:

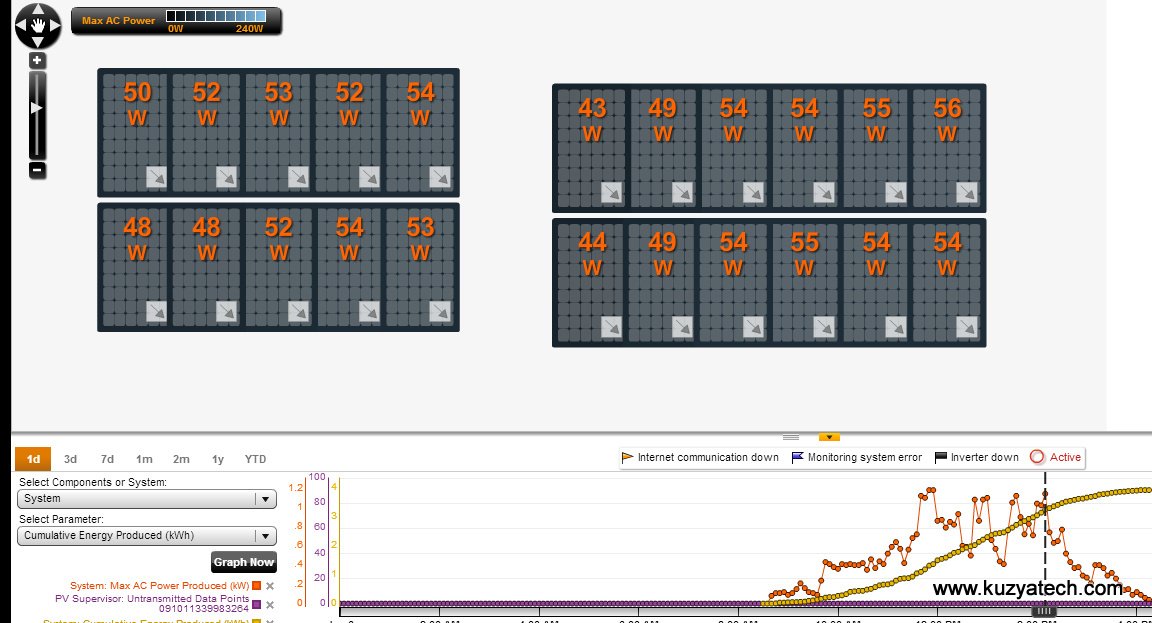

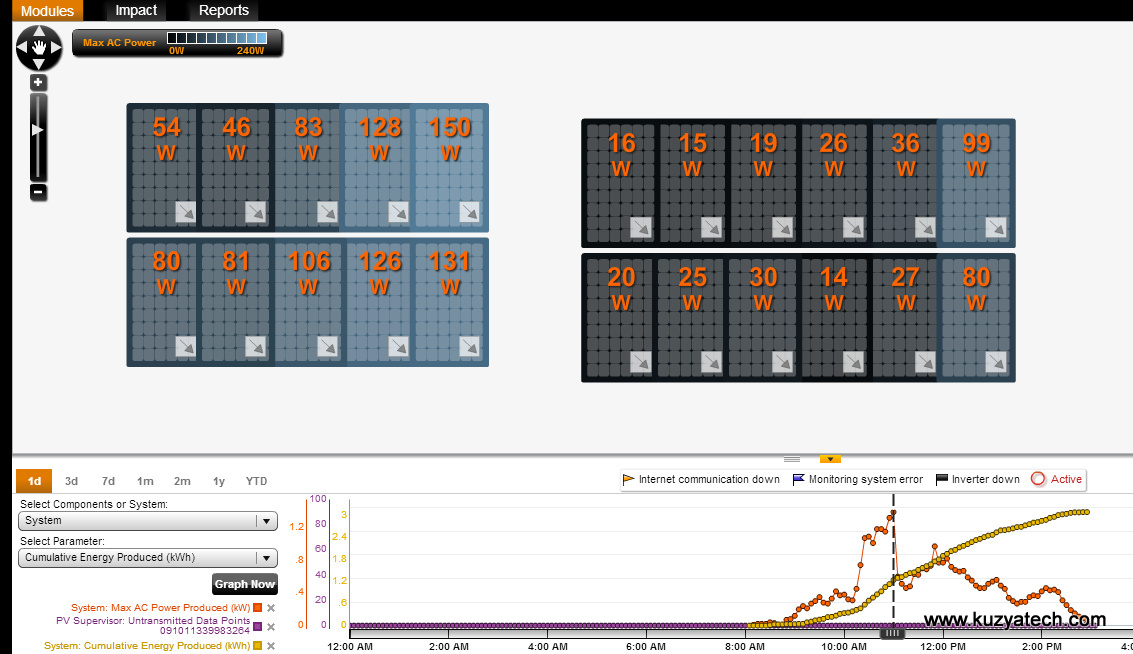

Observing the generation data from my system, we can see that the arrays get very uneven amount of light even when clean from snow. The winter sun is pretty low, so various obstructions get in the way.

Here is an example of evenly lit array- each panel is making about 50 watts

Let’s take another day:

Later in the same day, we have the first peak of the day, with a vast range of numbers generated- from 14W to 150W.

Were we to string all panels in each array serially, we can already see how much that would limit the amount of energy generated. All “weaker” panels basically end up a liability. In our system, they all just add up to the total.

Panel level Maximum Power Point Tracking.

Since each microinverter is attached to just one panel, its MPPT controller can optimize current drawn from the panel to stay on the highest power point just for that panel. As we saw above, lighting conditions vary widely panel to panel even on the same roof, so optimizing for one panel is bound to be better than trying to do that for an array

The inverter in the left array, upper right 163W panel is drawing 4.07A at 41.85V. The upper left 65W one is pulling 1.52A@46.44V – Vastly different maximum power points for the two.

The right array is a bit better matched, but again the 150W panels are running at about 42V@3.7A while the two leftmost panels are at 47V @0.73A for the upper and 45.7V@0.58A for the lower. As you can see- they are all over the place, but running happily since each one is fully independent.

No high voltage wires

Typical DC strings have high voltage DC wires running across the roof. With this setup, we have 40-50V DC behind the panel, and 240V AC from the panel to the house. If the grid is down, or a disconnect is pulled, inverters detect that and shutdown, de-energizing the wiring.

Resources:

- Solarbridge Pantheon microinverter datasheet

- Sunpower ACPV solar panel datasheet

- How shade affects solar arrays