Hey, it’s electric!

Today we have a crappy Chinese Tea Kettle to take apart and see what makes it not tick. This is an Ovente model #GK83R bought less than a year ago. It randomly refuses to heat and smells of molten plastic.

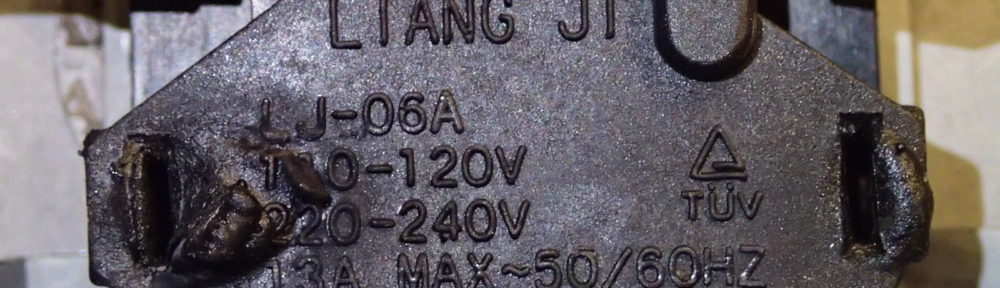

As expected, the product label does not even list UL/ETL or anything remotely resembling safety certification.

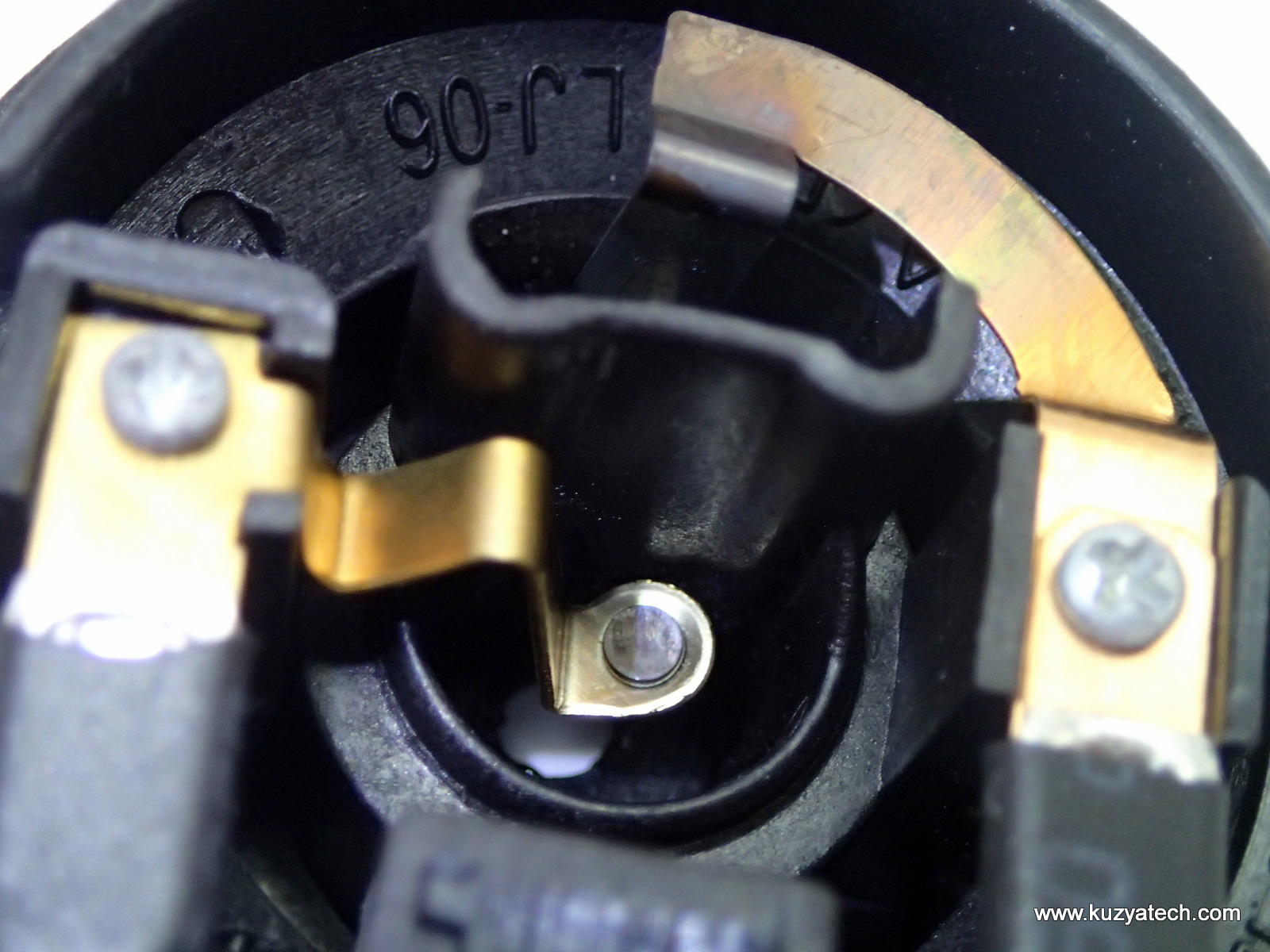

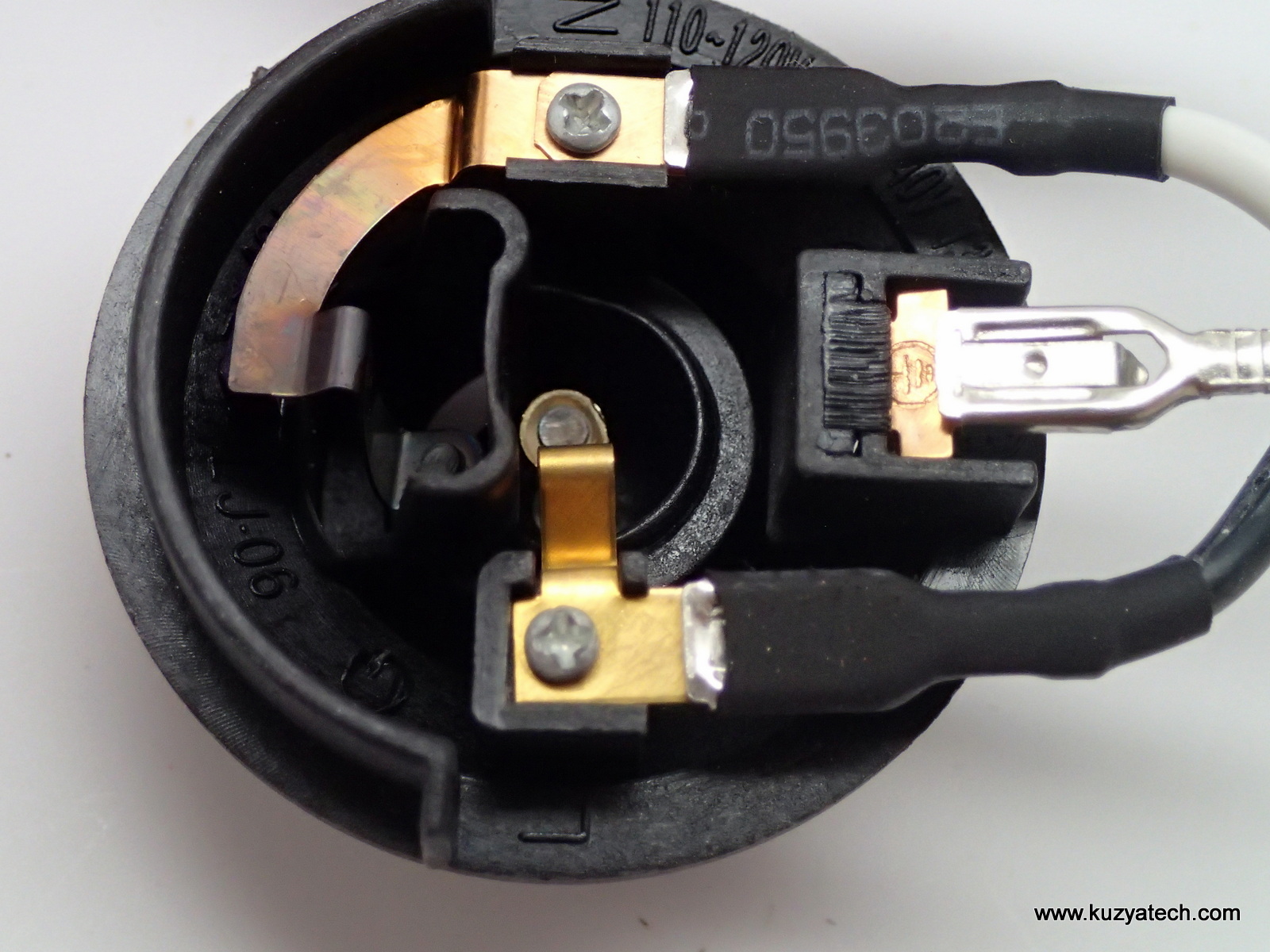

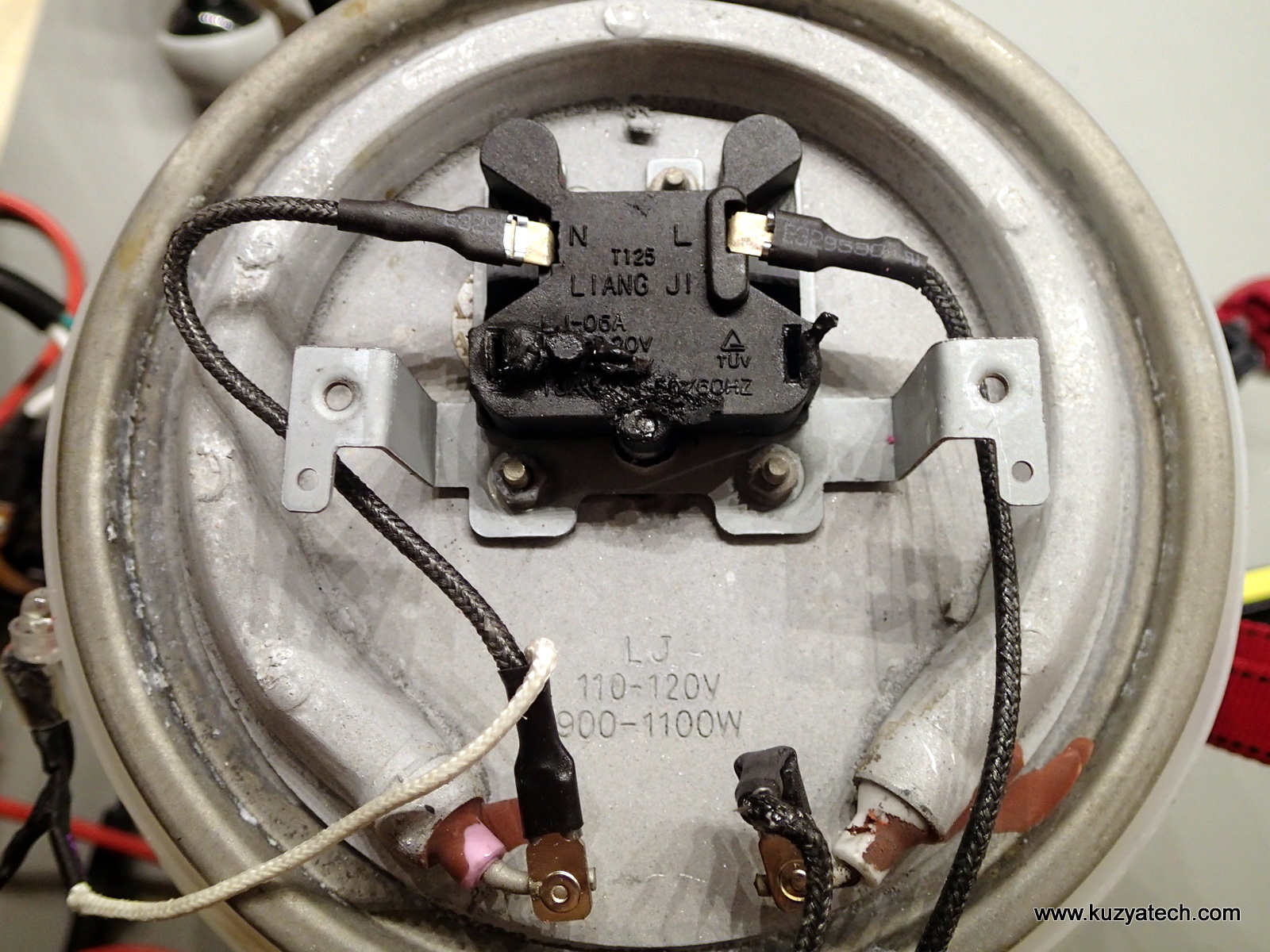

Let’s start with the base to make sure power actually gets in.

Power base

Taking kettle apart

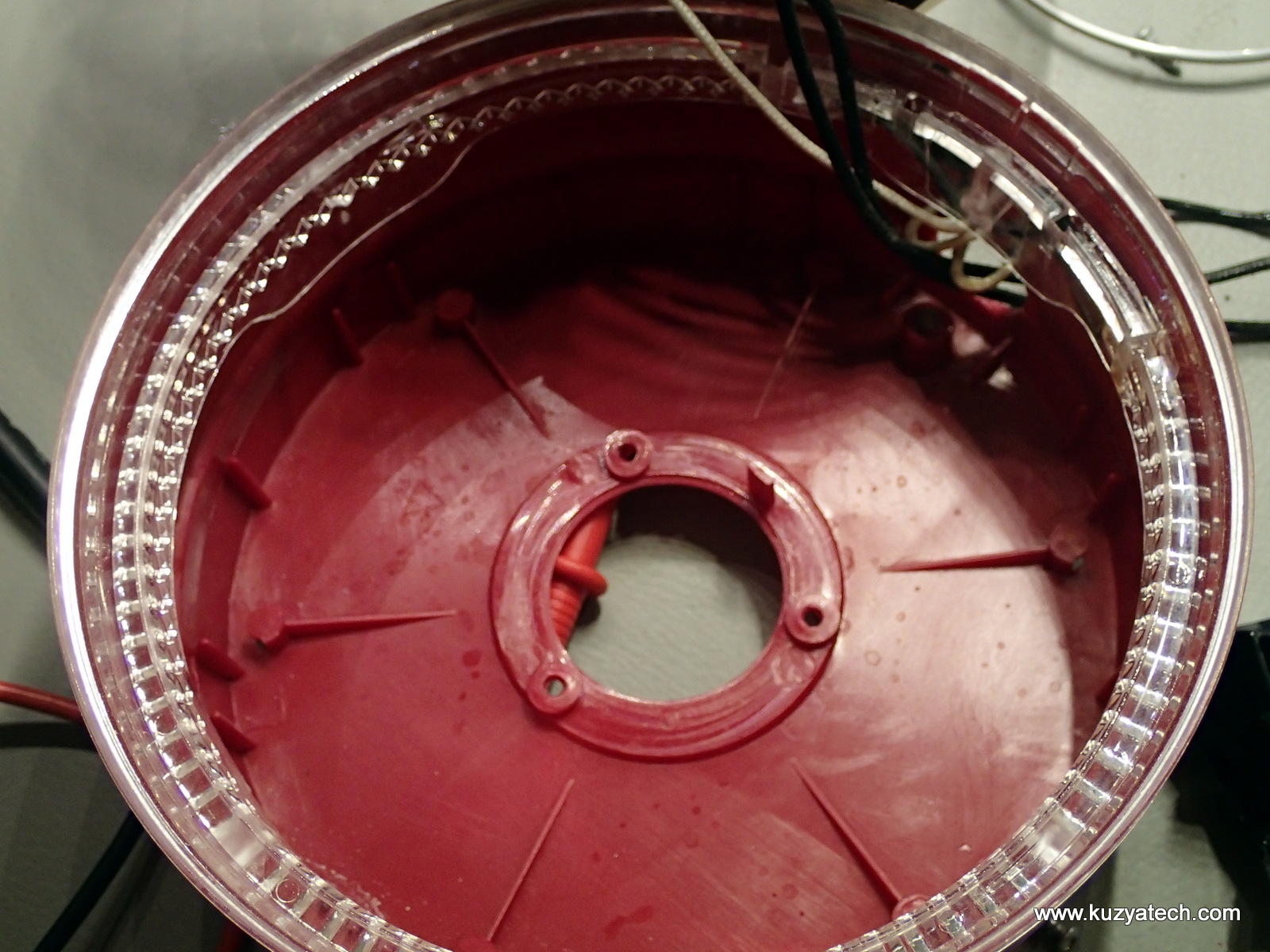

Now on to the actual kettle.To take things apart, we take out four the screws on the bottom

then pry two clips under the handle’s plastic insert from the top:

And finally remove it:

Remove one more screw under the wires and the whole glass carafe can be maneuvred off the kettle:

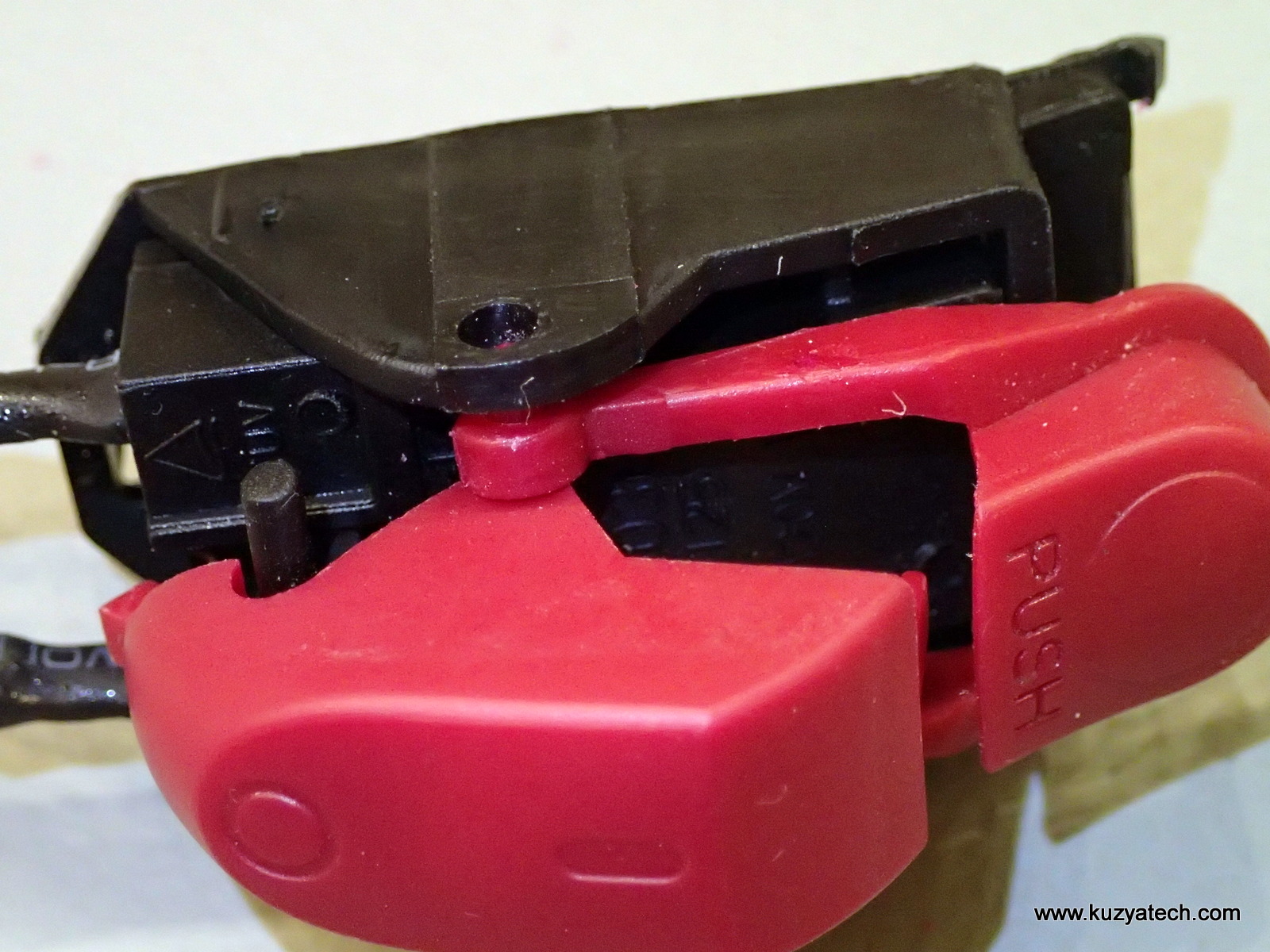

Power switch looks reasonable:

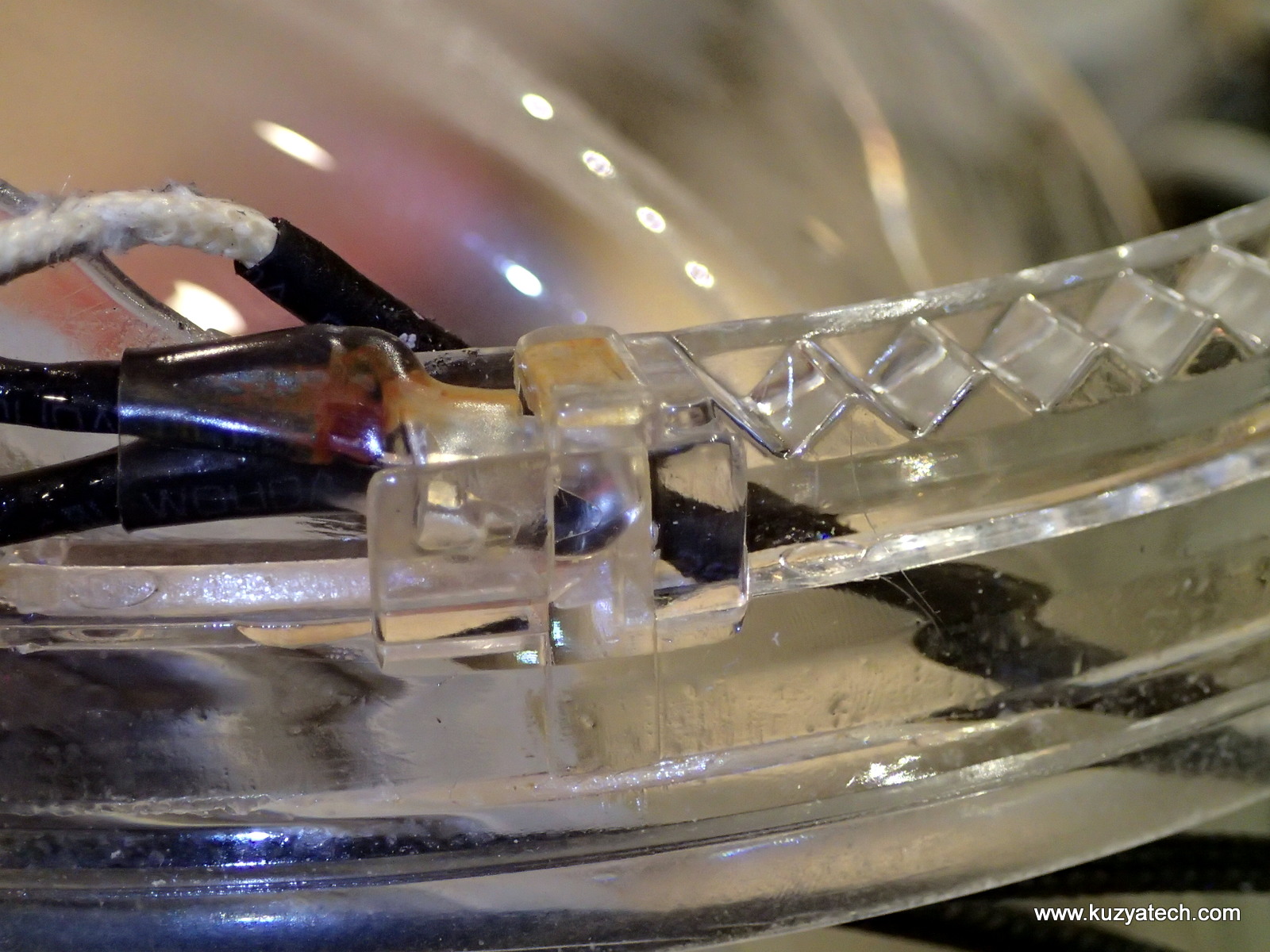

And this is how they drive these fancy blue LEDs:

The base holds a light pipe with two blue LEDs in it:

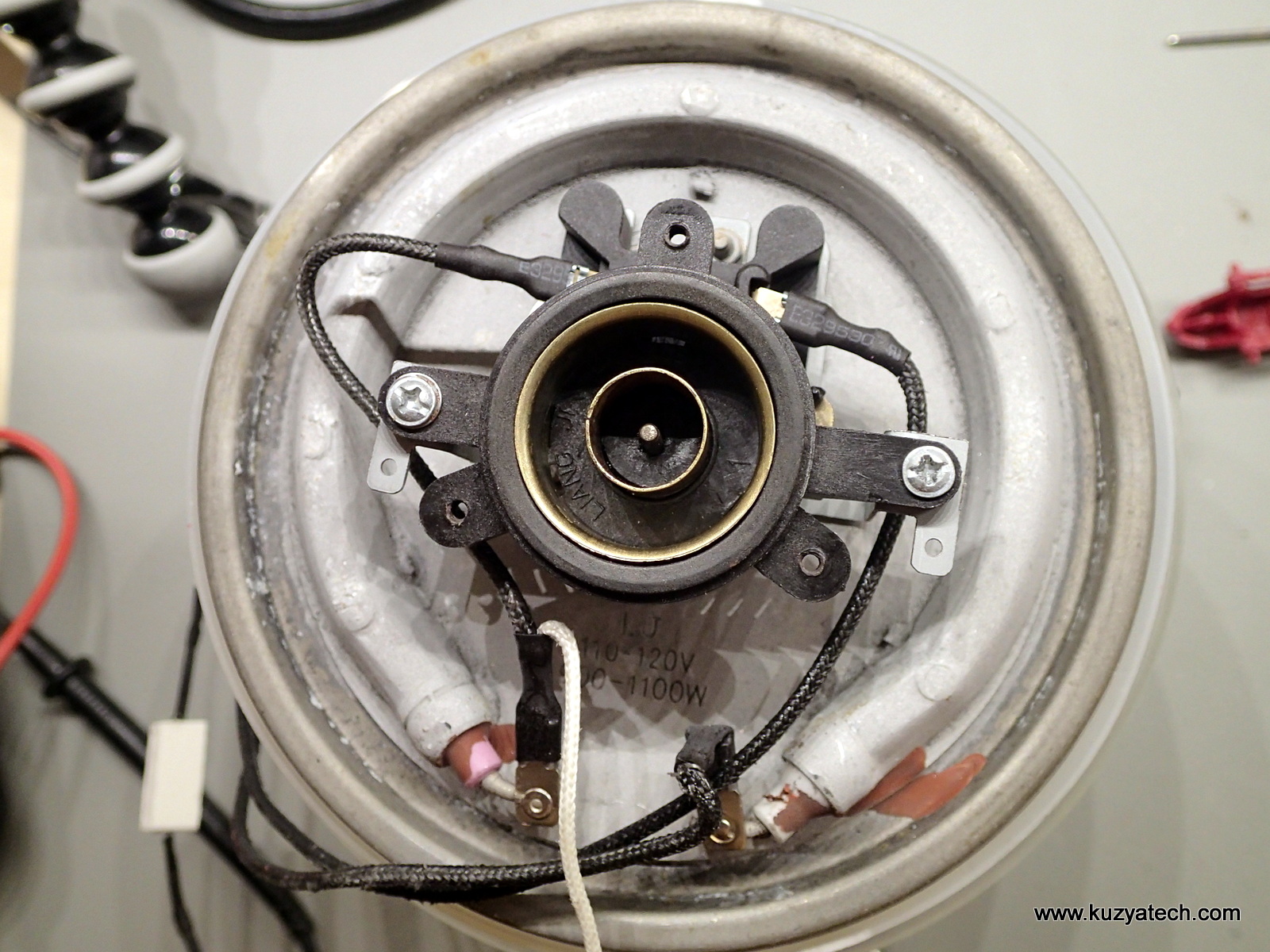

Now on to the actual heating element that’s bonded to the glass:

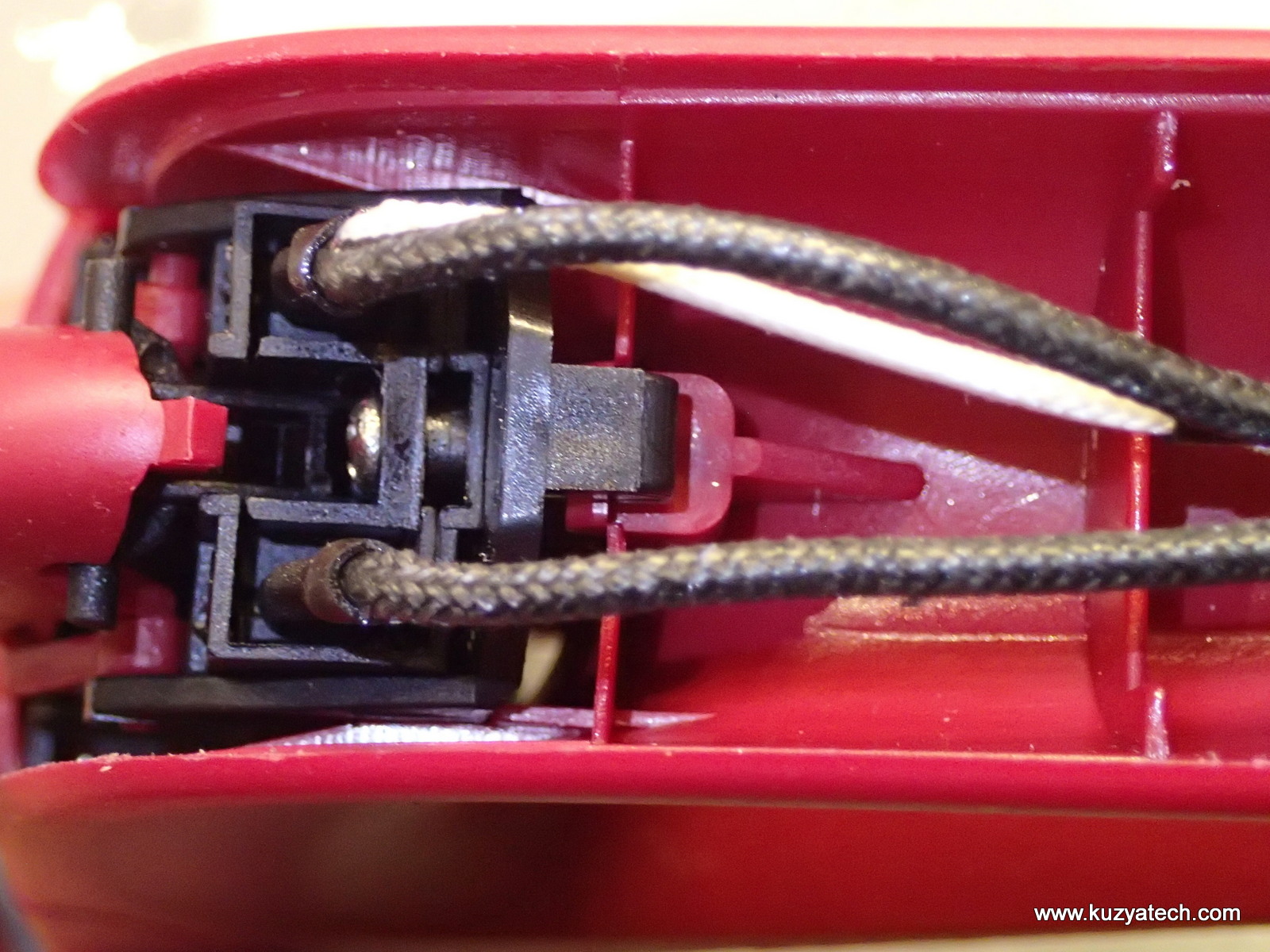

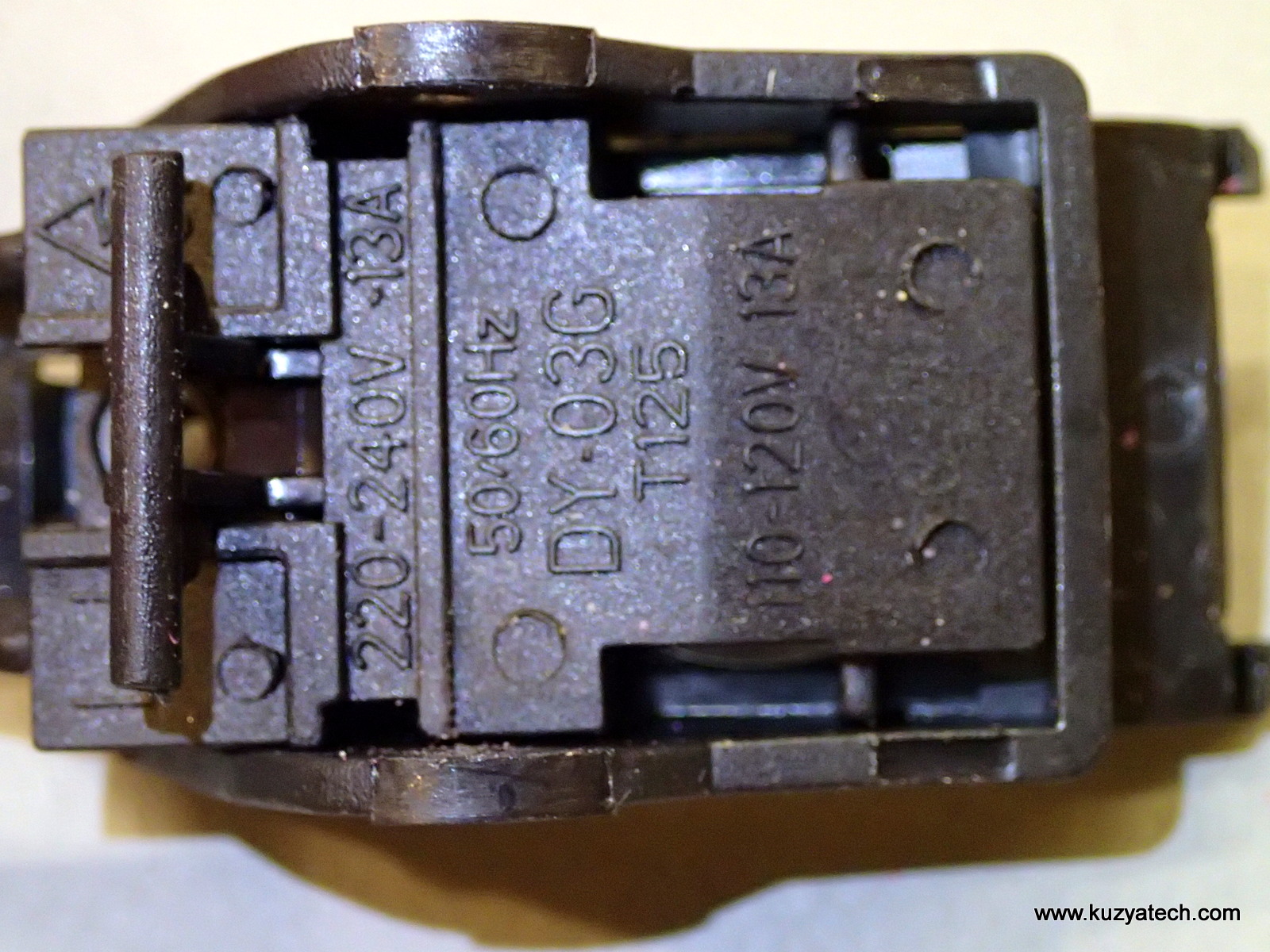

Taking power receptacle off, reveals the thermal switch housing with even more melted plastic.

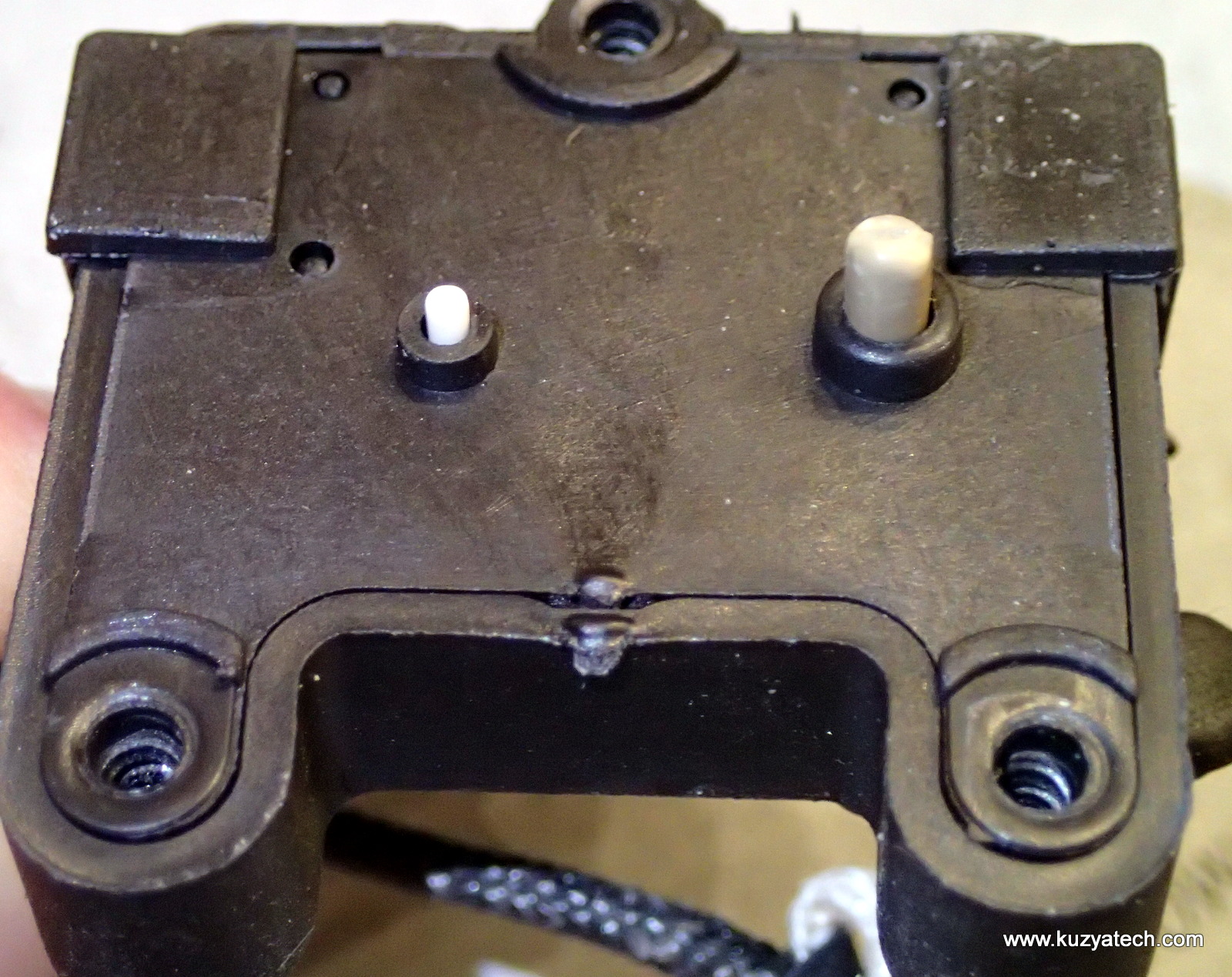

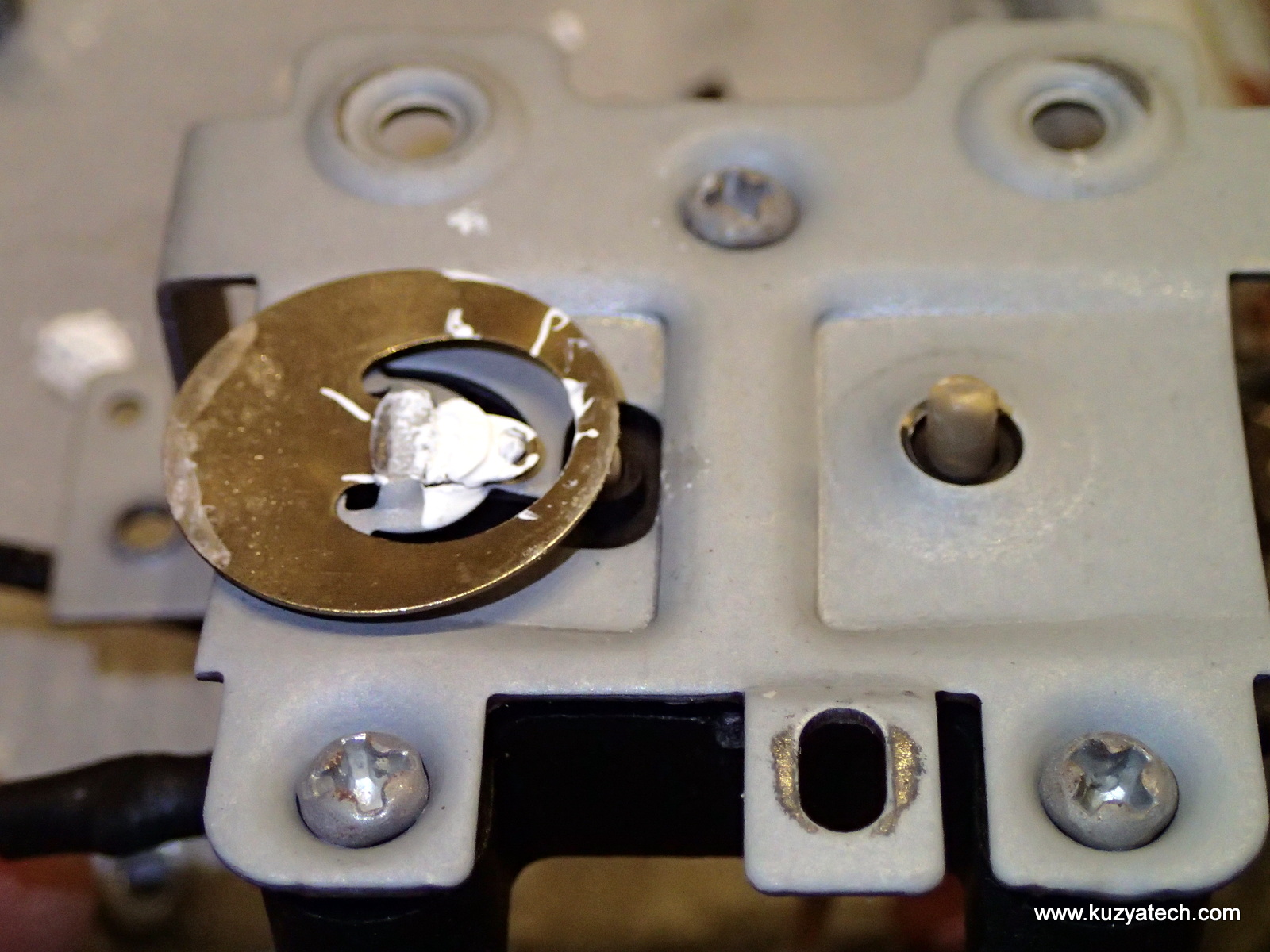

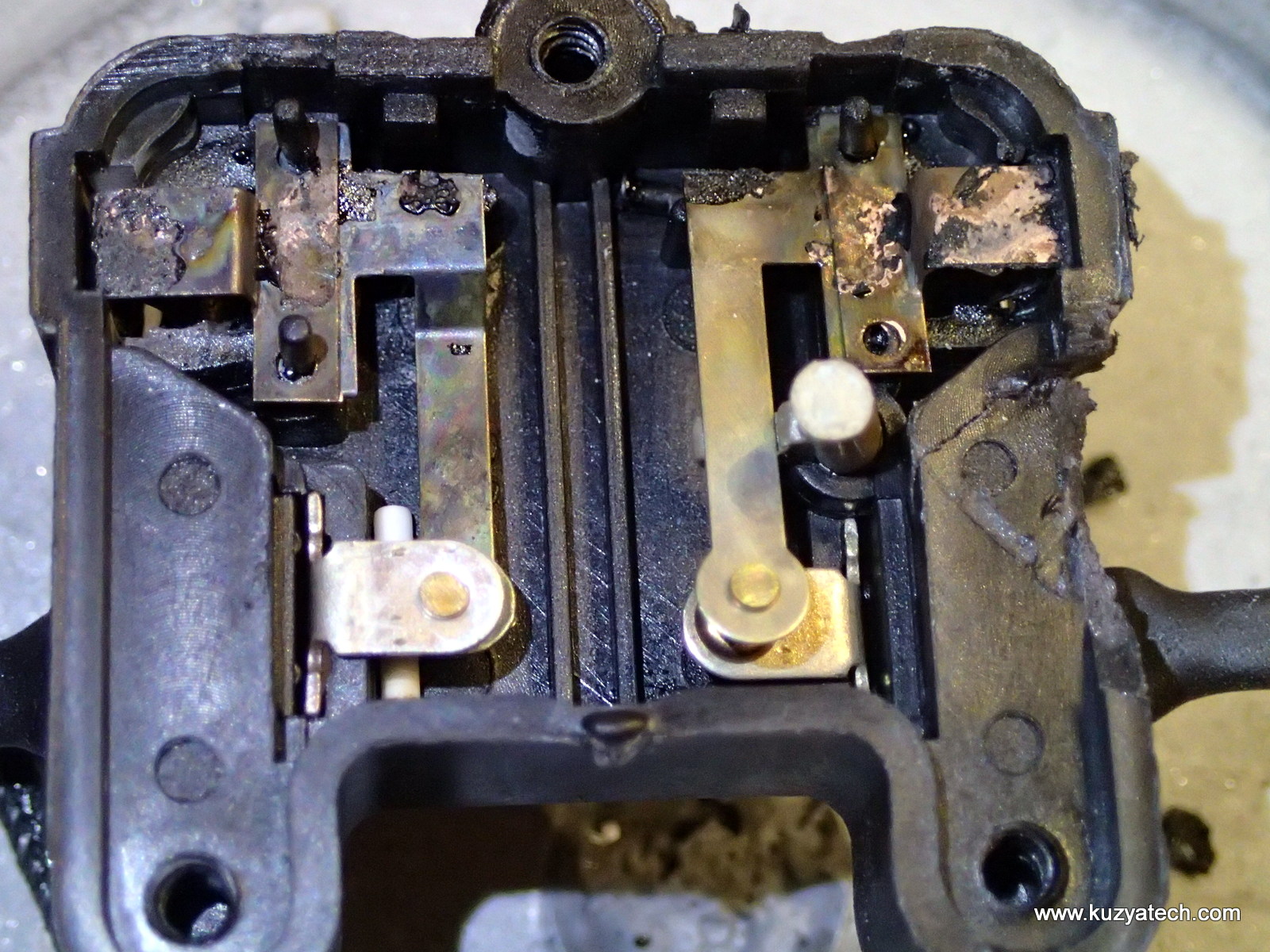

Seeing how the chance of finding replacement parts is fairly slim, we might as well proceed to destructive disassembly to learn how things used to work:

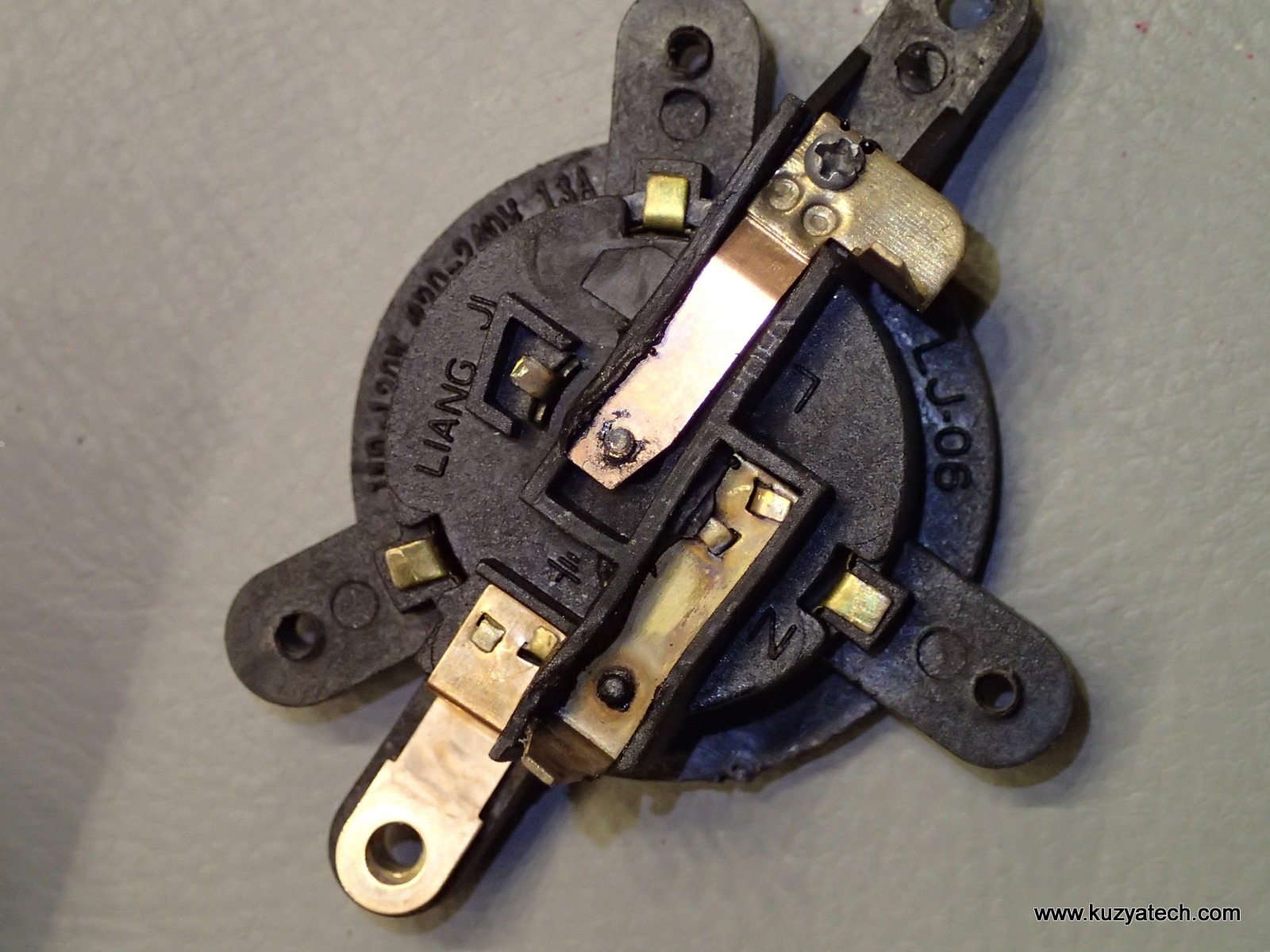

The two white actuators are depressed when installed. One by the base, another by a bimetallic sensing plate that changes geometry when heated:

And finally let’s take a look at the power switch and the boiling detection:

A plastic chamber directs steam to a bimetallic thermostat. Once it reaches trip temperature, the metal disk snaps and pushes switch reset pin in, shutting the kettle off.

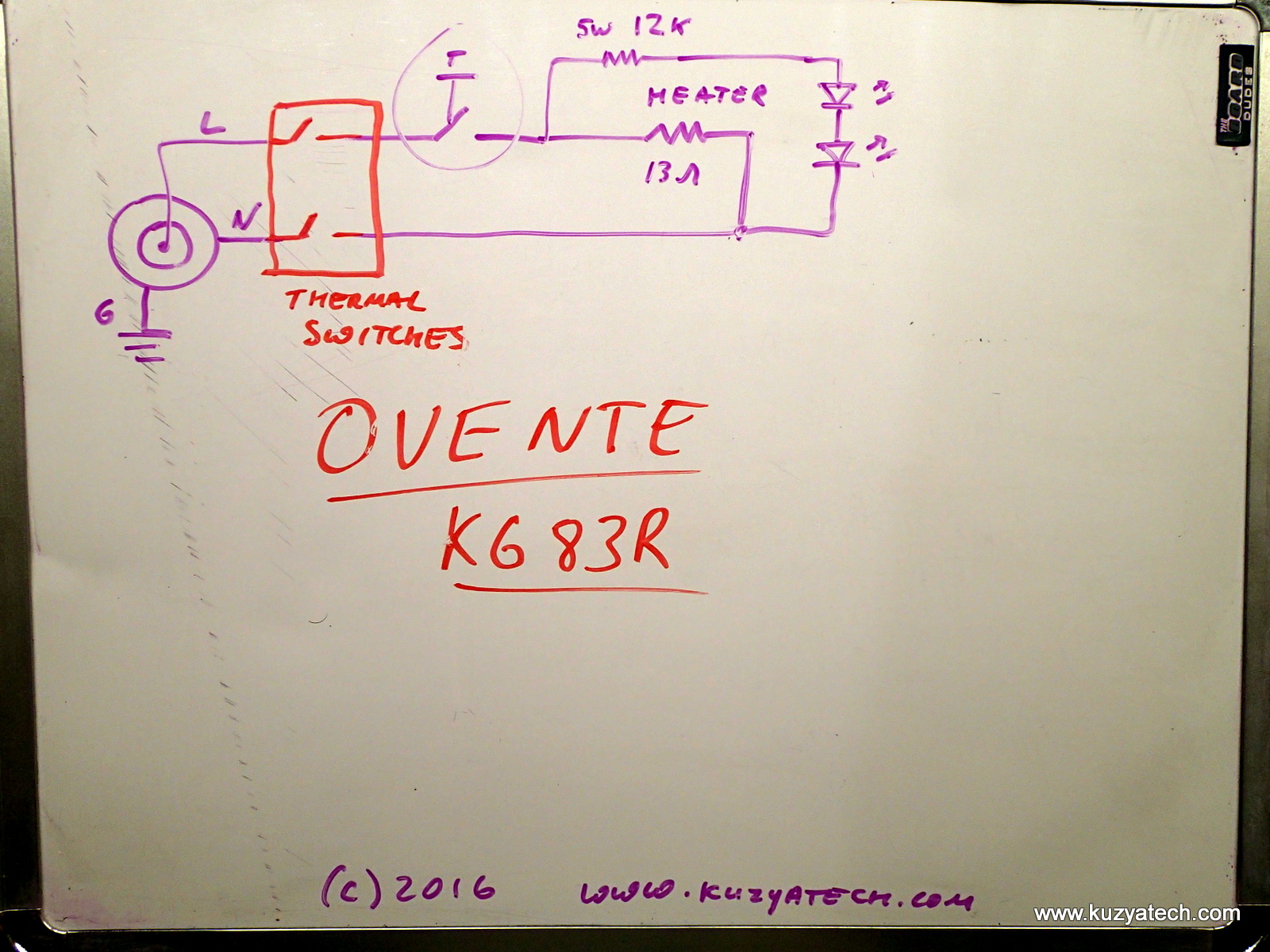

Schematic diagram:

It’s an “interesting” design. From safety point of view it is done reasonably well, with two series thermal switches and grounded frame. The LEDs are driven in series through a large resistor, though the way the are reverse biased on every other AC cycle is a bint cringe-worthy. Why not stick them in parallel and back to back so that one is always forward biased at any given time? As it is, they are most likely just getting away with it thanks to a large series resistance limiting reverse breakdown current. Plus it’s easier to wire- probably a non-trivial consideration for cheap volume build product.

Conclusion:

This teardown started as a quest to find out why the kettle is not working. It appears the weak design of power inlet and thermal switches resulted in way more heat being seen by parts than expected, melting thinngs and disconnecting Line circuit. Not much is fixable here, so the kettle is getting dismantled and sorted into recyclable parts and e-waste. Oh well, now we know what to look for in a new one. And don’t forget those safety certs!

You should report this product to UL, CPSC, and/or the FTC.

This device obviously shouldn’t be sold on the market … :/

Like most of the Chinese designed crap..

Hi, sorry for replying on such old post, but today I’ve dismantled similar kettle and indeed has similar issue in Liang-Ji LJ-06A T125 thermal cutoff, not as bad (yet) as yours. But while looking at it, I’m wondering what purpose does the thicker actuator (the one not covered with bimetal) has in this case.

It’s always depressed, because it’s not pressed by the kettle base, but by the heated plate which this cutoff is permanently screwed on.

The only time when this actually cuts the power is when you unscrew it (not very likely to be still under power) or when the plastic actuator itself melts down (or the heated base bulges up significantly), in both cases probably too late to be useful (and the other actuator should already cut it much sooner).

I wonder if removing the actuator and closing those 2 L contacts permanently instead would make it significantly more safe :).

Hi,

I have found this part (t125) in an electronic controlled kettle. Because it allows to set switch off temperature, there is a thermal sensors read by some microcontroller. I am not sure if there are some rules for home equipment like for SIL 3 (IEC 61508) devices, but adding an independent safety switch decreases probablity of failure on demand.

In my case, the problem was even worse. The plastic part melted and L (phase) contatcs moved and created transient resistence.

> I’m wondering what purpose does the thicker actuator (the one not covered with bimetal) has in this case.

Disassembled mine because it would not turn on anymore after I found it running on with no water (the lid was not closed so it did not stop). Guess the thicker one acts as a kind of fuse, because the brown pin it is molten now and due to the reduced length the switch is not connected anymore.

Yes I agree and that is what I did. If you want to make it more safe you can add a thermal fuse of 180°C to cut off power before any ‘melt-down’ of this unit.

Dump it. It is total junk. Serious design obsolescence. A major fire safety hazard.

Took apart kettle concept RK 4030:

https://www.tipa.eu/en/kettle-concept-rk-4065/d-216055/

and found this T125 safety switch there.

Too bad cannot find spare part anywhere.

I found this exact same wiring scheme in a Mueller glass tea kettle, which just goes to show I only paid for a labeling change. I suspect the Liang Ji T125 is also the culprit in mine – I never had a catastrophic failure like severe melting. One side does look a bit distorted, but the kettle sort of sputtered out and eventually stopped heating altogether. I’ll have to make sure future electric kettles I buy don’t include that component…

Have the same model. Broken today after 2 years of service. Reason was the LJ-6A part. The ever activated contact failed, increased resistance and with I*I*R this produced more heat on the contact. Other infrastructure still working. If I bypass this one contact, I can heat water. LEDs can be operated even cheaper using a capacitor (0,1uF), TVS diode and resistor. This would be cheaper than the power resistor.

Thanks a lot! I did removed the four screw but didn’t pry the handle as I don’t know the way, instead I removed connect pins and get handle, glass and bottom removed. Yours photo shows the part1/2 black module contact is poor and burnt, I also found the contact loss yet melt is at the bottom right of your photo, brass piece becomes grey and due to melt the contact has offset.

These contacts except for bi-metal dry protection is useless, I just ordered KSD-01F 105C and plan to use it to bypass the bottom switches, one existing stud can be used to mount KSD, original contacts in black boxes will be replaced by KSD and soldered wires.

teofil, I can’t find the switch via your link.pre thx for any link for handle power switch

please remove my previous comments. Based on your photo of module damage, the fix is: bypass the three contacts by direct soldering to bottom module pins, just keep the dry burn contacts.

Has anyone found a source for replacing the Laing thermal switch for the Ovente kettle?

Pingback: my turn to repair a Myland ETS1712 kettle with Liang Ji T125 & other common components – normalblog

I was given a kettle for repair where Liang-Ji LJ-06A was not working but it was in a good external condition. Thanks to this discussion, I was able to repair the switch.

I took it apart, as described here. and then I just cleaned and bent the contacts controlled by the thick stick so they make a better contact. Assembled everything and the kettle works!!!

Thank you !

I was given a kettle for repair where Liang-Ji LJ-06A was not working but it was in a good external condition. Thanks to this discussion, I was able to repair the switch.

I took it apart, as described here. and then I just cleaned and bent the contacts controlled by the thick stick so they make a better contact. Assembled everything and the kettle works!!!

Thank you !

Exact same thing as a MuellerLiving M99 Ultra Glass Kettle

Nice drawing and analysis. Just got a replacement from Amazon. First unit had a broken neutral contact in the base, out of the box. We’ll see how long this lasts!