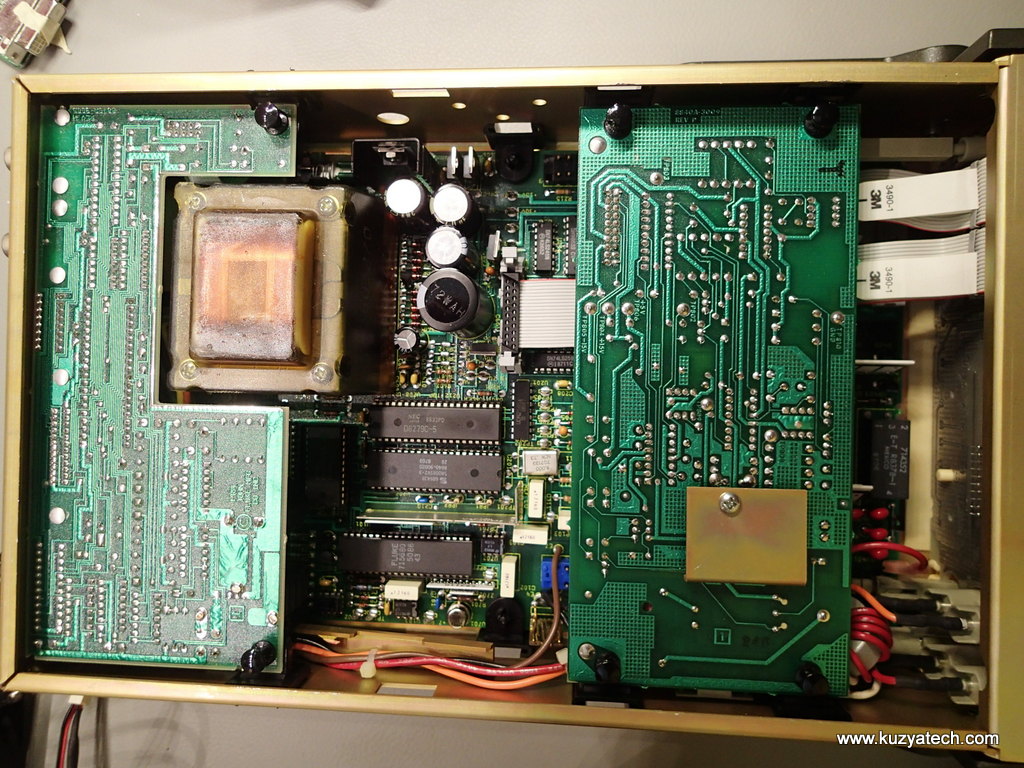

Today’s repair subject is a Fluke 8840A bench DMM that has some display troubles. It would work normally for a bit and then start fading out. A bit later it would come back and work again. The initial thought was that the display simply had too many run hours and is worn out. In that case a replacement is required and is not a very cheap solution. So before resorting to it, I decided to poke a round a bit. Luckily, the display was completely out when I turned the unit on. In attempt to bring it back, I started rotating the meter along various axis, and immediately the display returned. Oh, so not all is lost yet. We have a simple bad contact to chase!

The display board looked clean, well soldered and did not react to my prodding. I then decided to check the AC voltage coming into the display. That was a steady 4.6V until I pressed on the AC transformer. It would drop and then climb back. Ok, we have our target now.

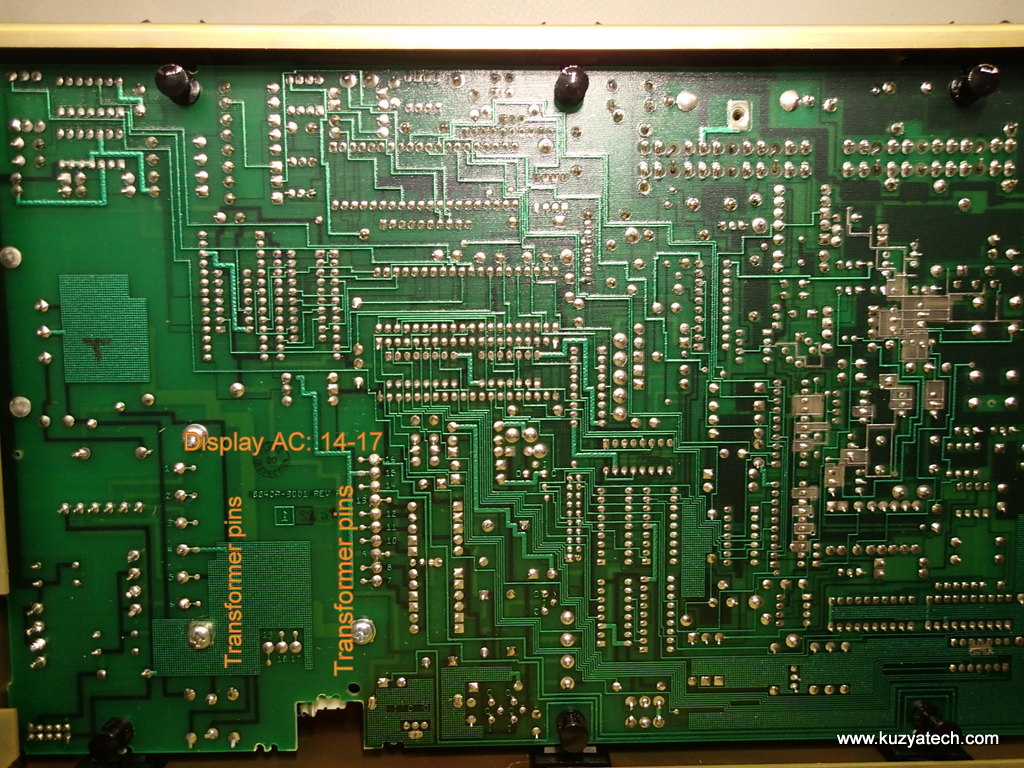

So either the solder pins of the transformer are not making good contact or somewhere on the board we have a break in the trace. All traces looked good, with no visible damage, so it’s back to transformer. As it happens, the board support bracket in the corner near it was broken, and the board was flexing quite a bit when I rotated the unit. A heavy transformer mounted right to it would certainly make matters worse. Time to look on the other side.

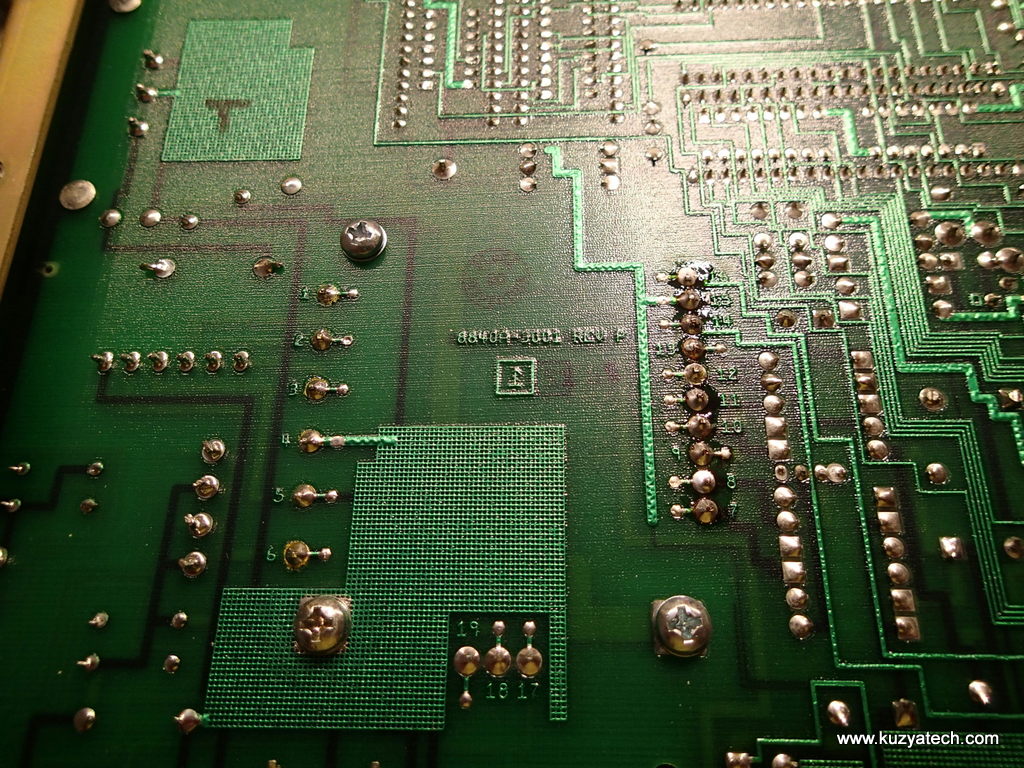

No visible damage anywhere, so lets try touching up transformer pins. As soon as the iron touches the pin, it becomes obvious that the amount of oxidation on them is enough to prevent solder from sticking. So despite the joints looking happy from the outside, there was no good electrical contact on the inside. With enough heat and flux, all joints are redone and the display problem is gone.

No matter how much I press on the transformer, the screen stays on. Now, on to reposition one of the plastic brackets from the less loaded areas of the unit and we are in good shape. Repair done- cheap and fast, just as I like them 😉

Here is a comparison shot of the repaired 8840A on top and a newer 8842A on the bottom.

Thanks for this info, I saved my fluke thanks to you

Thanks! I fixed several issues by resoldering!

Eric

Thanks for this! It fixed what I assumed was a dead display on my unit. Never would have thought to check the transformer solder joints.

Thank you for the great save on my Fluke 8840a. The problem drove me nuts for over a year as every time I opened it up to trouble shoot, the rascal started working. Some of the solder joints on the xfmr did look a bit dull and I hit them all for good measure. Spent more time getting the little plastic insulators back on the shield board that I did on the repair. Thannk you once again for the repair solution.

Bob Mille, KE6F

Brilliant report, many thanks, pointed me to the fault quickly, saved my 8840A!