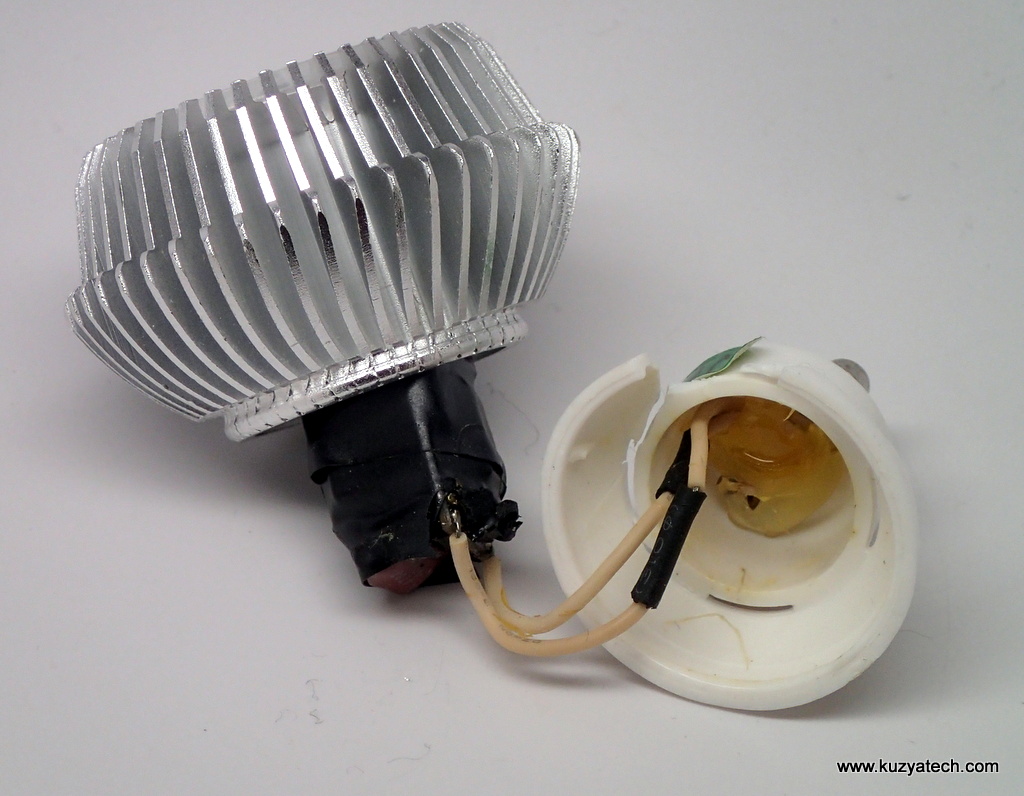

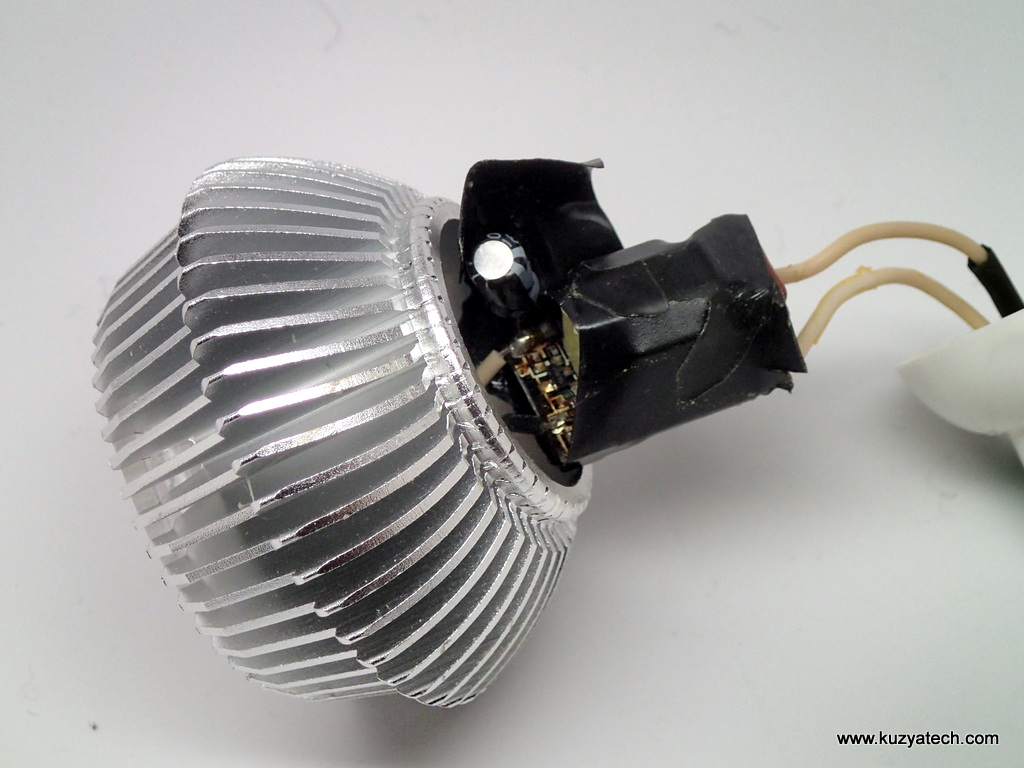

In the usual Kuzyatech fashion, when something breaks, we must take it apart. Today, one of the “early adopter” GU10 style LED lamps decided to fail mechanically:

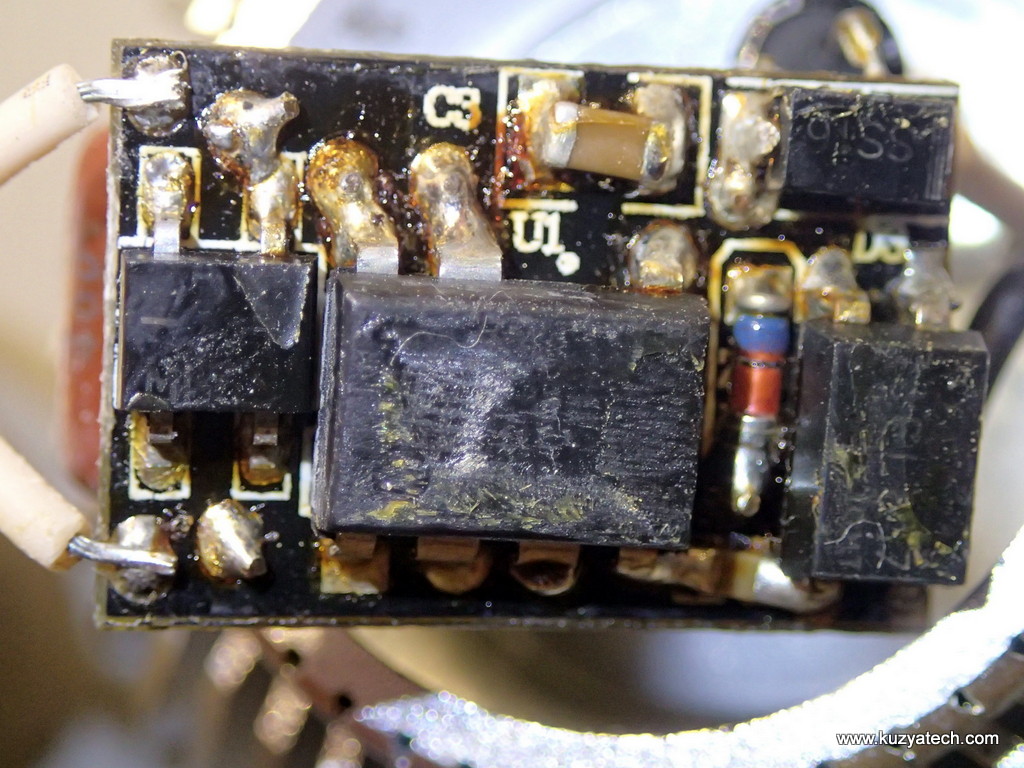

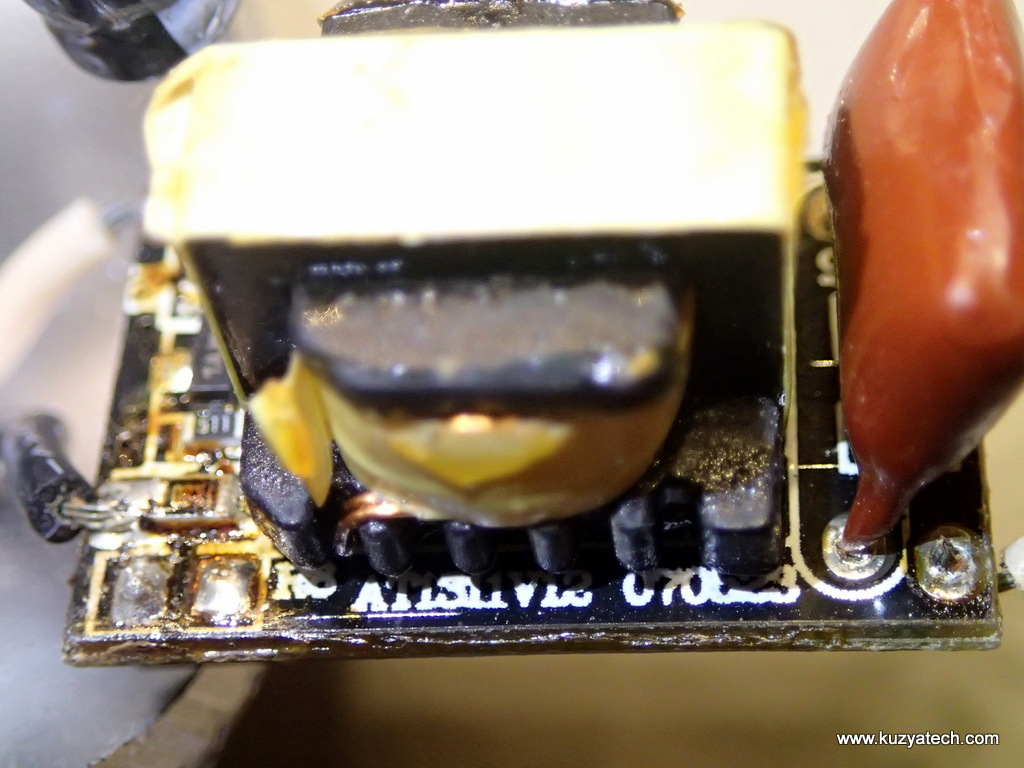

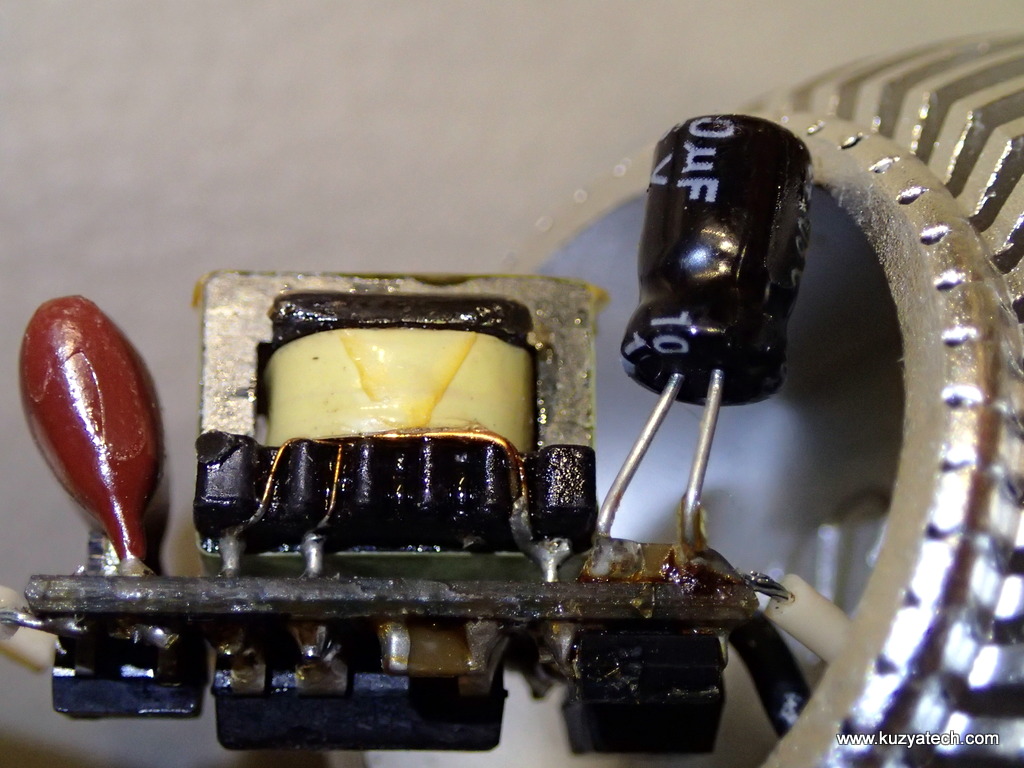

The power supply is wrapped in some tape. But that does not preclude a bunch of exposed mains line points from being visible

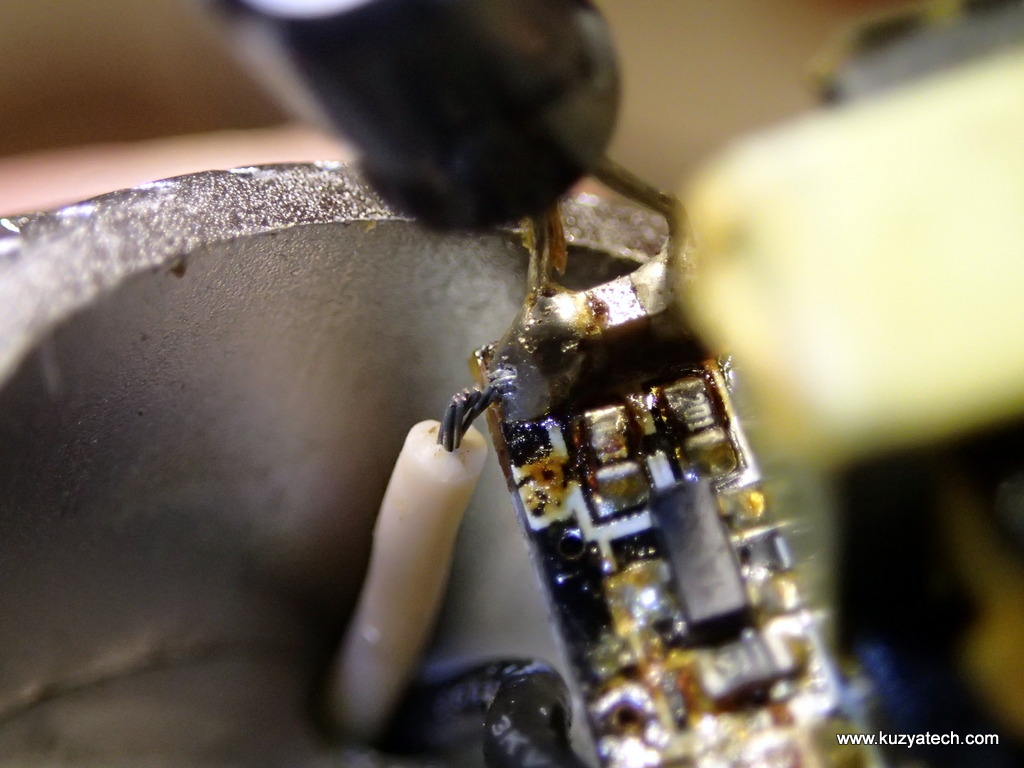

All part numbers sanded off. Diode bridge on the left, controller IC in the middle, optocoupler on the right. Clearance distances- nowhere to be found

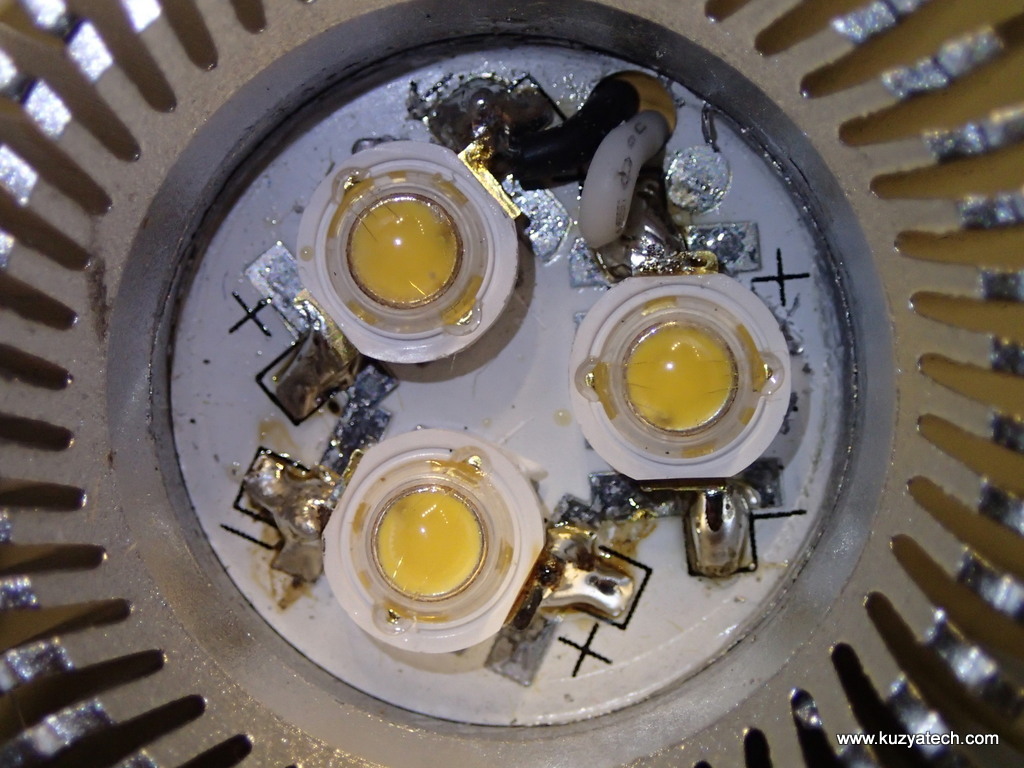

The lamp uses SHP brand Heatsink/lens combination. LEDs appear to be handsoldered to the metal clad board, with very questionable solder joints

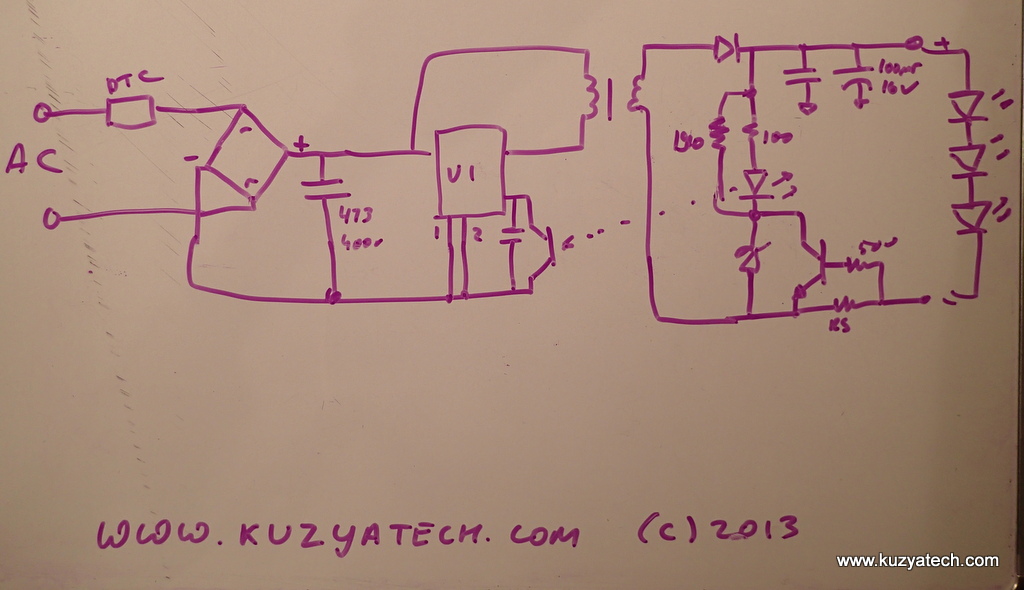

And now to the everyone’s favorite part- reversed engineered schematic diagram. What we have here is basically an isolated (if we ignore for a moment the total lack of clearances between various nodes) power supply with voltage and current feedback. The density of parts and their relative location is such that I doubt this will ever pass any safety tests, but it does seem to work. Thinking that this hazard ran for years makes me stop before buying any new no-name lamps!

Looks like TinySwitch-II from Power Integrations

http://www.powerint.com

http://www.powerint.com/sites/default/files/product-docs/tny263_268.pdf

I think you have to correct your schematic though 🙂